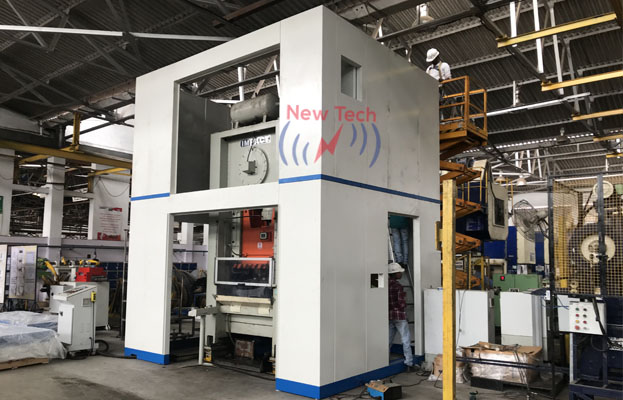

Newtech established in 2002 and going as strong as ever with a strong customer base in manufacturing and supplying sound-proof enclosures, sound-proof glass windows and doors. Our comprehensive range of products has perfect finish, smooth edges and durability. Catering to diverse requirements of our clients, we fabricate our spectrum of noiseless fittings as per the specifications of our valued clients.

As a part of our mission to achieve maximum client satisfaction, we offer various after sale service such as maintenance, service & repair of our products. We employ a combination of technological expertise and ethical business standards, to ensure the quality of our products and customer satisfaction.

Our workforce is a primary factor in establishing the status and repute of our organization in the market. It comprises of different teams of experts such as:

Our workforce is a primary factor in establishing the status and repute of our organization in the market. It comprises of different teams of experts such as:Our staff is highly talented and experienced in the field of manufacturing sound proof enclosures and windows. They also assist in the development of products as per the drawings or blue prints made after client’s inspection

For optimum output and achieving maximum client satisfaction, the organization has set up a well equipped manufacturing unit in an area of 1800 sq. ft. Furthermore, we have installed the latest machinery which works on advanced technology to ensure uninterrupted production. Today, we are capable of producing 40 units in a month and during peak season we will go beyond this limit. Our set of state-of-the-art machines includes the following machines:

At Newtech Engineers, we have separate departments for each process like procurement, production, quality check, marketing and customer care which assure smooth business operations. The departments work in close coordination with each other to manufacture products in a stipulated time.

We can capably manufacture customized products according to the specific requirements of our clients. Customization of products is done on following parameters

We adopt a systematic procedure for developing customized products for our clients. Firstly, we make a personalized inspection and site evaluation and take noise readings with our high-tech noise level meter. Then we prepare a detailed quotation. Only after receiving the order, we prepare blue print for the approval and manufacturing of the required equipment. We strive to provide full satisfaction to our clients by delivering quality products in a mutually decided reasonable time frame.

We deliver trust to our customers, through our superior quality products. There is a close monitoring of all the processes, in order to minimize wastage and improve efficiency. All our noise controlling products are tested on the basis of the following quality parameters that are continually improved through research and development.